Whether used in water bottles or food containers, automotive parts or textiles, polyethylene terephthalate — commonly called PET — has become an essential part of modern life. Thankfully, it is also one of the most widely reused plastic materials, and PET recycling offers a way to reduce plastic, conserve resources and create a more sustainable future.

What is polyethylene terephthalate (PET)?

Polyethylene terephthalate, a member of the polyester family, is a lightweight and versatile polymer represented by the formula (C₁₀H₈O₄)ₙ. Its chemical structure gives it strong physical stability, making it a popular general purpose resin used in bottles, food packaging, textiles and more.

Polyethylene recycling

To quickly identify the resins in plastic containers and bottles, the Society of the Plastics Industry (known today as the Plastics Industry Association) introduced SPI symbols (now called Resin Identification Codes). RICs, typically found inside the “chasing arrows” sign, use numbers 1-7, but they do not indicate recyclability; they identify what plastic a product is made of.

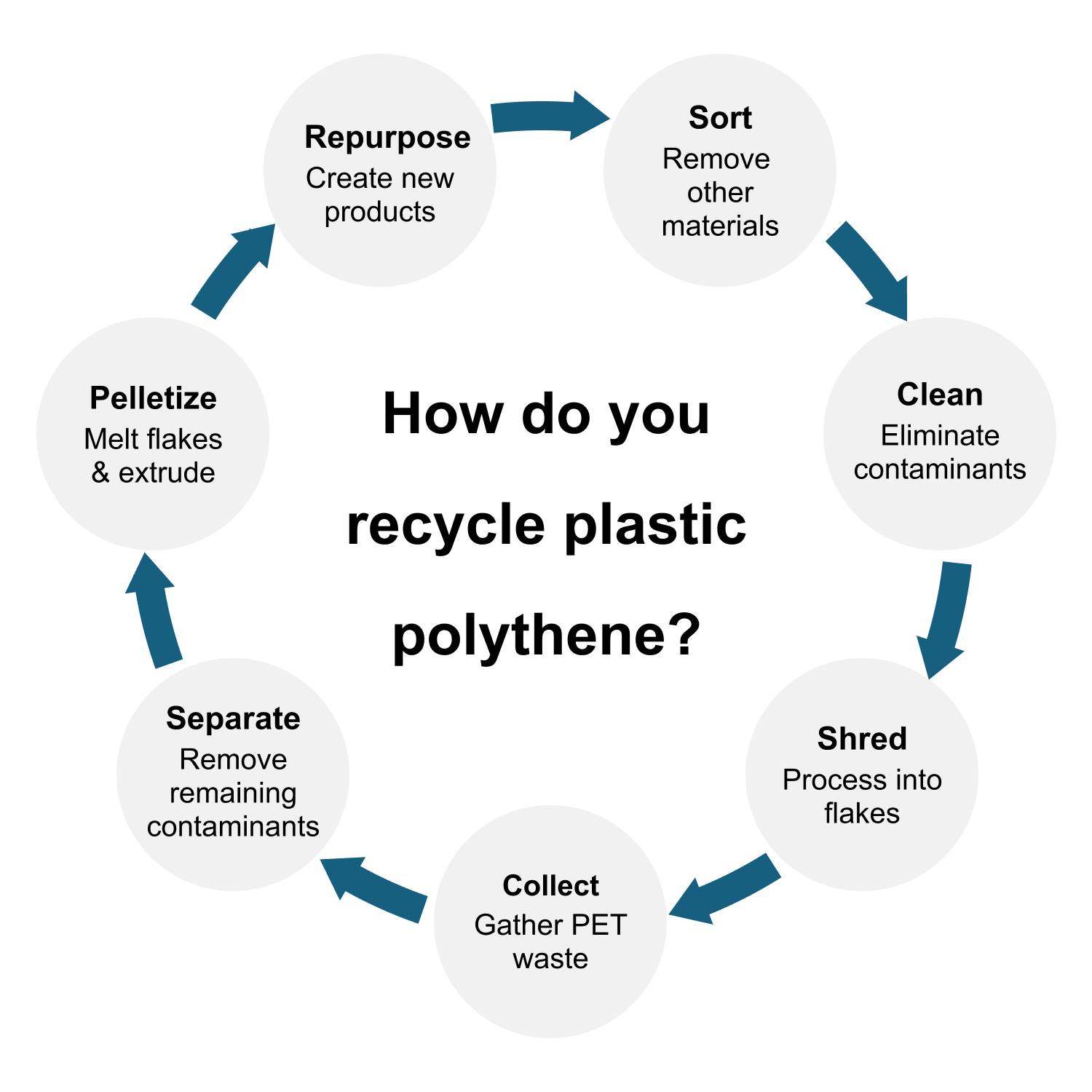

As one of the most widely reused plastics worldwide, PET is highly recyclable and is critical to reducing plastic waste. Identified by the RIC code “1”, it is easier to recycle than polyolefins (like polyethylene and polypropylene) because of its chemical structure and thermal properties. Recycling PET is done in two ways:

- Mechanical: PET is washed, shredded and remelted into recycled PET (rPET)

- Chemical: PET is broken back into its original monomers and re polymerized

Using a low-cost, established infrastructure, mechanical recycling creates a sustainable material that maintains its quality and features. However, it has limitations when dealing with contamination, which has increased the chemical recycling of polyethylene’s popularity because it creates near-virgin quality material and handles contaminated PET.

From recycled plastic sheets to PET bottle recycling, repurposing PET (regardless of the method used) is vital to advancing the circular economy. Its reuse extends material life by leaving it in circulation longer, reduces the need for new raw materials, consumes less energy during production and encourages manufactures to consider end-of-life recyclability during the design process.

5 things you should know about PET

As the most widely recycled plastic globally, it’s no wonder there are a lot of questions about PET plastic recycling. We’ve addressed a few of the most common ones here.

Q: Is polyethylene 100% recyclable?

A: The answer is tricky, but the bottom line is — not really. Although chemical recycling goes a long way towards 100% recyclability, it isn’t as widely used as mechanical recycling, which can’t always separate mixed polymers (i.e., when PET is combined with other plastics). Once polyethylene is contaminated, it cannot be recycled into high-quality products.

Q: Is polyethylene biodegradable?

A: No, PET is not biodegradable. Its long chains of hydrocarbons can withstand the natural degradation processes by microorganisms like bacteria or fungi.

Q: Is low density polyethylene recyclable?

A: Yes, LDPE is recyclable; however, its thin and lightweight characteristics make it challenging to handle and complicate the process. Standard facialists frequently turn away LDPE materials because the cost of processing is too high for the weight-to-volume ratio.

Q: Is HDPE recycling possible?

A: Yes, high-density polyethylene (HDPE) is widely recycled, but the process differs from PET because it has unique chemical compositions and physical properties. HDPE tolerates higher temperatures during the recycling process, allowing it to be repurposed more frequently before degradation occurs. Recyclable HDPE is identified by the recycling code “2” inside a triangle.

Q: What are renew plastics?

A: This blanket term encompasses the efforts to generate eco-friendly plastic solutions like materials from recycled content and renewable resources or innovative production methods that reduce environmental impact.

PET Recycling: Transforming Plastics

PET is easier to recycle than other general-purpose resins, and resin manufacturers around the world are taking advantage of this characteristic and leading the way to establish PET recycling initiatives.