Cars. Computers. Aeronautics. Electronics. Packaging.

The list of plastic products seems infinite, making it almost impossible to consider the modern world without plastic. Its versatility, low cost, and durability make it the backbone of innovation.

Today, we explore this vital material that touches our everyday lives.

Plastic molecular structure

Modern plastic is a broad classification of synthetic or semi-synthetic materials. Plastic raw material consists of monomers and polymers. But what is the difference between monomers and polymers?

- Monomers: Small molecules that are the building block of polymers

- Polymers: Large molecules made up of long, chemically bonded chains of repeating molecules

The types of monomers used to form a polymer chain determine the chemical properties of plastic and vary significantly based on the material being created.

What is the common property of plastic?

While every plastic has attractive and one-of-a-kind features, there are several common plastic material properties. So, what properties make plastic unique?

- Weight: Plastic material density is typically low, which makes it much lighter than other materials like metal or glass.

- Resistance: Durable plastic is ideal in harsh environments, including chemical exposure, extreme wear and abrasion, water and more.

- Electrical properties: Plastic does not conduct electricity, making it perfect for housing electrical insulation for wires and cables.

- Elasticity: Plastic is flexible, making it easy to process and mold into countless shapes and sizes based on industry and needs.

- Sturdiness: Plastic's tensile strength varies depending on its type and composition, but its ability to withstand stress is high.

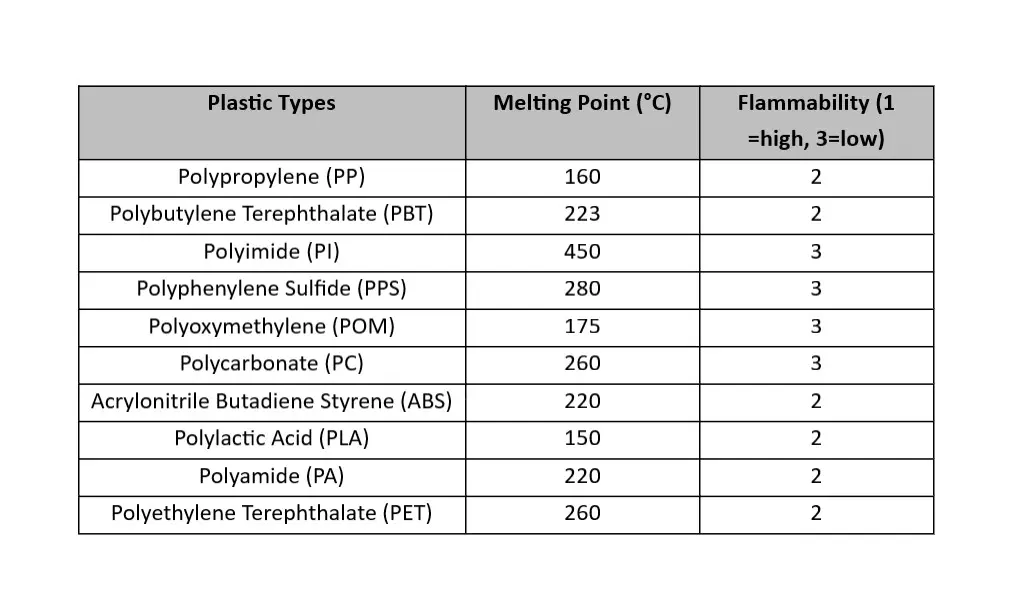

Additionally, melting points and flammability are important to plastic material properties. This table outlines the melting point and ranks the flammability of 10 widely used plastics.

Different types of plastic

In previous articles, we have discussed several types of plastics, including:

- Polypropylene (PP): PP's higher melting point makes it useful for food and beverage containers, medical equipment, and pipes and tubing.

- Polyamide (PA): Known as nylon, this strong and durable plastic is frequently used in textiles and mechanical parts.

- Polycarbonate (PC): Valued for its transparent look and high impact resistance, PC is often used for eyeglasses, bulletproof glass and electronics.

- Polyethylene Terephthalate (PET): Renowned for its light weight and ability to preserve freshness, PET is commonly used in beverage bottles and as packaging for personal care items.

- Polyimide (PI): A heat-resistant plastic found in aerospace, automotive and electronics parts

The above are considered conventional plastics, but research and production of bioplastics are growing. While conventional plastics use non-renewable fossil fuels, bioplastics use renewable resources like cornstarch or sugarcane. These emerging plastics, like Polylactic Acid (PLA), have a lower carbon footprint because they are designed to be biodegradable.

Driving progress

Shaping everything from advanced technology to daily essentials, plastic has revolutionized countless industries worldwide, and researchers continue to explore its potential. From developing smart plastics and enhancing durability to creating new recycling techniques and ocean-friendly materials, the evolution of plastics carries on.