“Is polycarbonate strong?” It’s a simple question with a simple answer: Absolutely.

Impact-resistant polycarbonate is over 250 times stronger than glass, 5 times stronger than ABS, and 50 times stronger than polyethylene and acrylic. So, how does it have this much strength? Let’s explore that question.

What is PC material?

Polycarbonate is a thermoplastic polymer made from bisphenol A (BPA), phosgene (COCl₂) or diphenyl carbonate. The molecular backbone has repeating units of carbonate groups linked with aromatic rings, and the structure is represented as: -O-(C₆H₄)₂-C-(CH₃)₂-O-CO-.

There are two manufacturing methods for PC:

- Phosgene (solvent): Reacts bisphenol A (BPA) with phosgene

- Transesterification (melt): Reacts bisphenol A (BPA) and diphenyl carbonate with phosgene

The method used depends on the polycarbonate chemical compatibility needed. The solvent method exposes PC to materials, potentially create stress points that reduce chemical resistance over time. Conversely, the melt method preserves chemical resistance long-term since there is no exposure to solvents during the development process.

PC characteristics

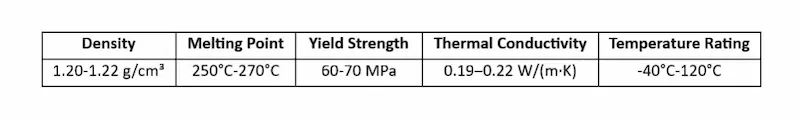

The density of polycarbonate makes it lightweight compared to metal and other plastics; however, PC density isn’t its only appealing feature. Polycarbonate thermal conductivity, melting point of polycarbonate, polycarbonate yield strength and polycarbonate temperature rating give it the rigidity and strength, thermal stability and impact resistance it’s known for. The chart below outlines some key figures:

Also important to note is polycarbonate’s transparency; at a thickness of 2mm to 3mm, the light transmittance is 85% to 90. This visibility and the ability to resist impact is essential for polycarbonate glazing or PC as a glass replacement in things like windows, skylights, auto windshields and protective barriers. Glazed PC can be tinted, frosted or used clear for different levels of lighting needs.

How is PC processed?

PC is an easily processable material that is compatible with most basic molding methods, such as extrusion, vacuum, and blow molding. However, one of the most popular and widely used methods is polycarbonate injection molding. It’s also used in fused deposition modeling for 3D printers because it creates high-volume, high-precision parts.

PC is not only simple to process but is also becoming a favorite mold-making substance. Polycarbonate molds offer minimal sticking and can withstand moderate heat. Additionally, the polycarbonate texture, which is naturally smooth and transparent, allows for high-quality final products with very little post-processing work needed.

Once processed, cutting polycarbonate with fine-tooth saws is preferable. These traditional methods are recommended over laser cut polycarbonate because the necessary temperatures can leave rough edges and may result in harmful fumes.

Is polycarbonate recyclable?

Yes, polycarbonate is recyclable, but less common than other plastics. Polycarbonate recycling has challenges, including whether local facilities are equipped to handle it and the type of recycled PC. Many PC products, especially those in electronics, contain additives that complicate the process. Additionally, there are environmental and health concerns about recycling polycarbonate containing bisphenol A (BPA) into packaging or containers that could encounter food or beverages.

PC: Tough and transparent

Thanks to countless properties that make polycarbonate ideal for demanding applications that require impact and stress resistance, transparency and heat tolerance, PC is used across industries worldwide.