Polyimide (PI): Defining Heat Resistance

Polyimides have varying molecular structures, but polymers with imide bonds are collectively called PI.

24/08/2025

By Web Editorial Team

Polyimides have varying molecular structures, but polymers with imide bonds are collectively called PI.

24/08/2025

By Web Editorial Team

Eager to find a resin with extraordinary thermal conductivity, scientists at DuPont began working on the first polyimide materials in the mid-1950s. By the early 1960s, PI was commercially released under Kapton (a polyimide film) and Vespel (a solid, molded polyimide). Due to its heat-resistant properties, PI quickly found its way into aerospace and electronic applications — including the Apollo space missions. Since its initial discovery, PI research has significantly expanded its applications, and today, studies are focused on sustainability and environmental impact.

Polyimides have varying molecular structures, but polymers with imide bonds are collectively called PI. There are multiple categories:

While all polyimide resins have similar properties, the science behind film or molded products differs.

Since PI can’t be melted after being created, the raw materials must first be dissolved to get a polyimide film. This means acid anhydride and diamine are added to a solvent and polymerized to create polyamic acid (an intermediate polymer). The polyamic acid is formed into a film and then imidized (reacted).

Unlike above, PI-molded product materials can be melted post-creation. Like film, the raw materials are dissolved to produce polyamic acid (an intermediate polymer) but are immediately imidized (reacted) to produce PI powder. The PI powder is then sintered and molded.

Despite its strength and rigidity, PI is surprisingly versatile. Thermoplastic PI uses standard methods like blow molding, extrusion and thermoforming during processing. However, thermosetting PI can’t be processed the same way and uses special methods like casting and curing, compression molding and others to form fibers and complex shapes.

Polyimide structure makes it indispensable to countless industries, including aerospace, automotive and electronics. Notable features include:

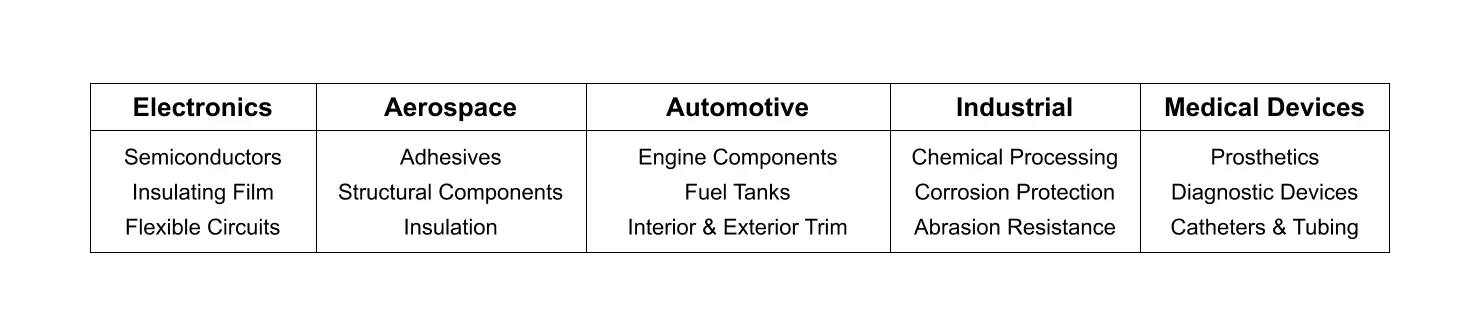

While not as flexible as other plastics, PI’s unique combination of properties makes it ideal for a wide range of consumer, medical and industrial applications like:

Q: Can you explain polyimide vs polyamide?

A: Both are polymers with unique chemical structures. Polyimides are best in high-heat and chemical-resistant applications like aerospace and manufacturing. Polyamides have more versatility with strong processability for use in consumer goods and similar industries.

Q: What are the disadvantages of polyimide?

A: With higher material costs than other polymers, PIs can be expensive and difficult to process. It can lack color stability, is susceptible to moisture absorption and may become brittle at lower temperatures. Additionally, there are environmental and sustainability concerns.

Q: Is polyimide a nylon?

A: No. Both are polymers, but they have different chemical structures and properties.

Q: What are examples of polyimides?

A: The most highly used polyimides include Kapton® (DuPont), Vespel® (DuPont), Upilex® (Ube Industries, Ltd.), Pyralin® (Hitachi Chemical Co., Ltd.) and Apical® (SKC Kolon Pl, Inc.)

Q: Is polyimide recyclable?

A: PIs are difficult to recycle through conventional means. However, since thermoplastic can be melted and re-used it does have a longer life cycle than other thermoset PI.

29/01/2026

By Web Editorial Team

2min read

17/01/2026

By Web Editorial Team

1min read

20/12/2025

By Web Editorial Team

2min read

02/12/2025

By Web Editorial Team

2min read

Copyright© 2026 PlaBase. All Rights Reserved.