Previously, we discussed polyimide (PI), a strong but versatile linear polymer known for its high heat resistance. Often referred to as polyimide film (e.g., Kapton) — the brand name for a specific type of polyimide film developed by DuPont — polyimide material is ideal for a wide range of consumer, medical and industrial applications.

What is polyimide?

PI is the ISO abbreviation for polyimide. Polyimide resin has various molecular structures, but polymers with imide bonds are collectively called PI. Since it cannot be melted, the raw materials must first be dissolved to get a polyimide film. This means a dianhydride and a diamine are reacted in solution to form polyamic acid. The polyamic acid is formed into a film and then imidized (thermally or chemically cyclized).

PI falls into two categories: thermoplastic and non-thermoplastic (thermosetting). Today we focus on non-thermoplastic PI

Polyimide material properties

Even though non-thermoplastic PI requires special processing methods like casting, curing and compression molding to form fibers and complex shapes, it remains a popular choice thanks to its unique combination of properties, such as:

Thermal: Thermal stability up to 400 °C; inherently low flammability without added flame retardants.

Mechanical: Exhibits an elastic modulus of 2.5–4.0 GPa and a tensile strength of 100–200 MPa (Kapton can reach over 200 MPa)

Electrical: Shows high volume and surface resistivity; dielectric strength of 200–300 kV/mm.

What are examples of polyimides?

PI is indispensable to several industries where high-performance materials are needed to tolerate extreme conditions. Two popular polyimide uses include polyimide tubing and polyimide tape. Although tubing and tape have the same base material, they serve different purposes and are used in distinct applications.

- Polyimide tube: Thin, flexible tubing

- Polyimide tape: Polyimide film coated with a heat-resistant silicone adhesive

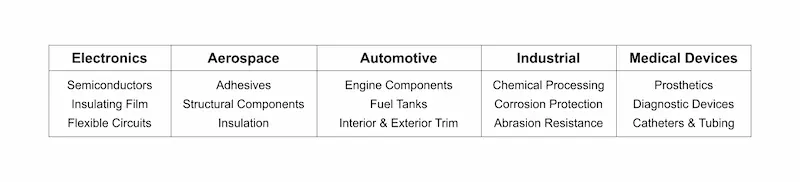

You will also find PI in:

What are the disadvantages of polyimide?

Despite its popularity, PI does have some downsides. It is typically more expensive and harder to process, making it difficult to use when budget is a factor. Its dimensional stability is challenged when exposed to moisture, and it becomes brittle at lower temperatures. Perhaps the biggest drawbacks are the environmental and sustainability concerns. Not only requires substantial energy and hazardous solvents to process, but it also has limited recyclability and is not biodegradable.

Polyimide: Extreme-Condition Ready

With its exceptional thermal stability, chemical resistance, electrical insulation and more, PI is an ideal choice for high-performance applications in extreme conditions.