It’s well established that engineering plastics have become indispensable to modern manufacturing. But when it comes down to it, is one superior to the rest?

Of the five major engineering plastics, polyoxymethylene (POM) stands out as the most-used premier resin thanks to a unique combination of properties. Thanks to its high mechanical strength, ease of processing, and versatility, POM fulfills the demanding requirements of industries worldwide.

Let’s explore polyoxymethylene (POM).

The history of POM

While studying the basic structures and behavior of polymers in the 1920s, Nobel Prize-winning chemist Hermann Staudinger laid the foundation for the development of synthetic polymers like polyoxymethylene. Unfortunately, in the early days, these polymers were unstable, and it wasn’t until the 1950s that significant advancements in stabilization were made. Commercial distribution began when DuPont began producing the homopolymer "Delrin" in 1959, and Celanese began producing the copolymer "Celcon" in 1962. POM research continues today with a focus on bio-based alternatives and environmental impacts.

What is Polyoxymethylene(POM)?

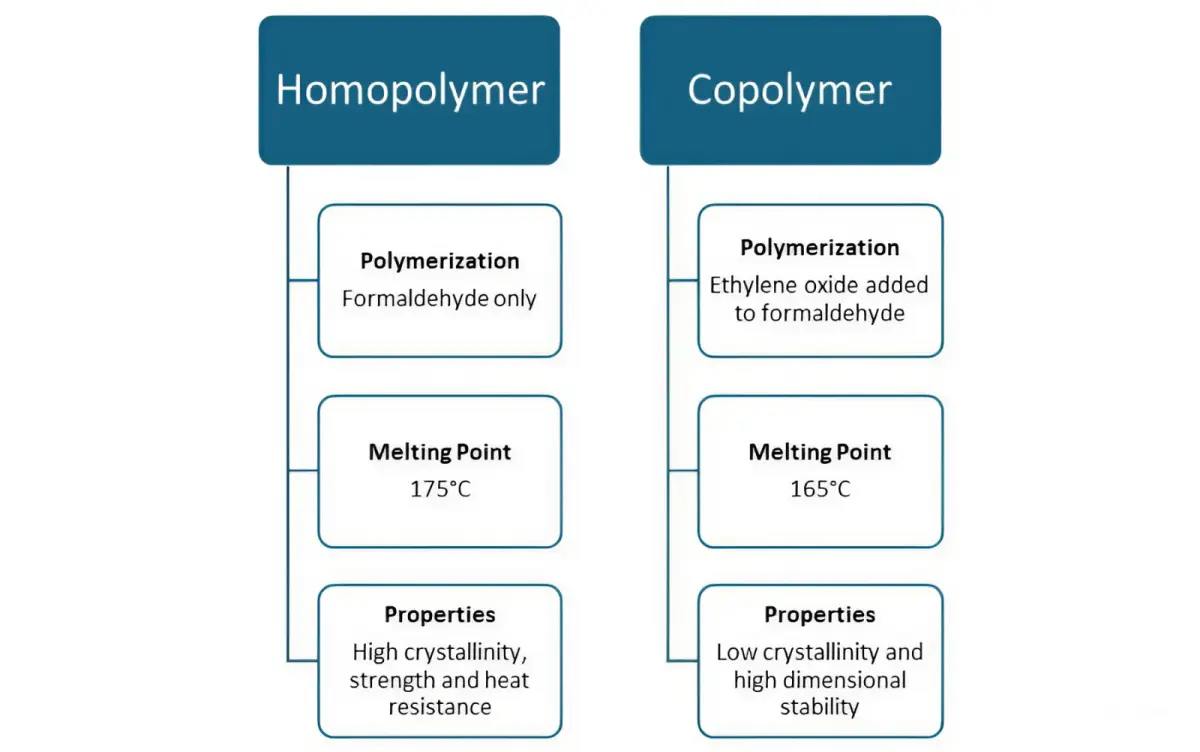

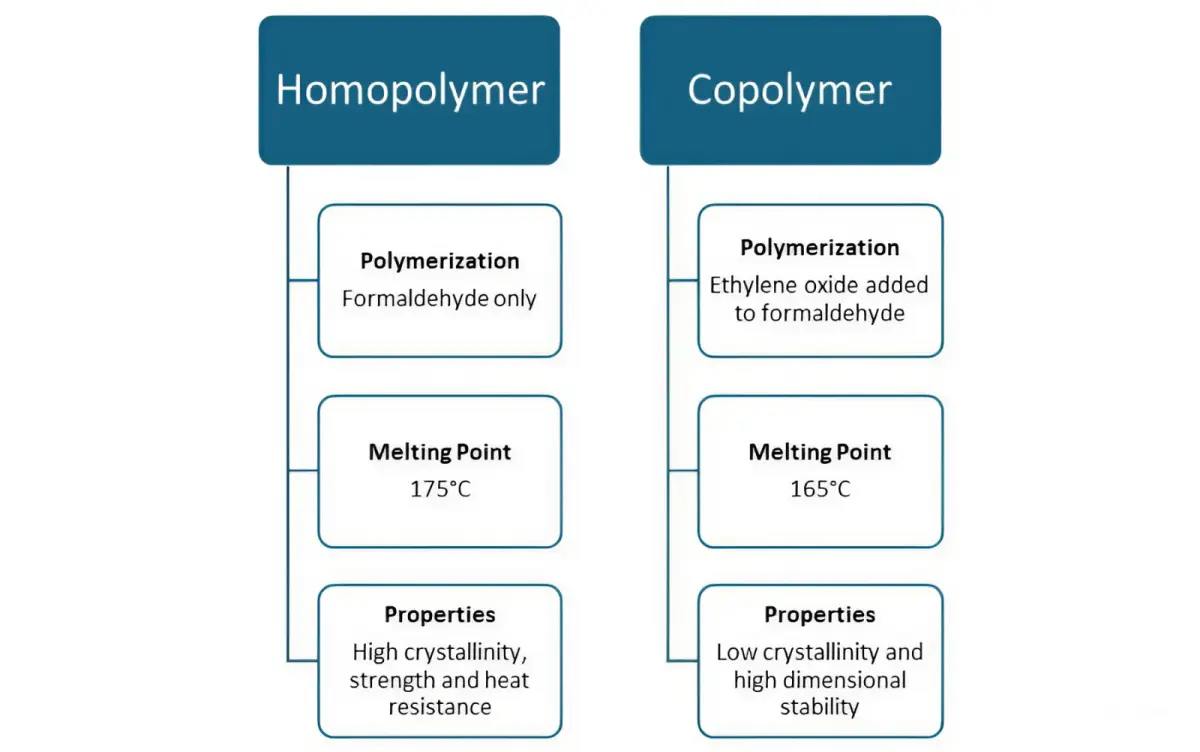

Polyoxymethylene, also called polyformaldehyde or polyacetal, is a polymer with oxymethylene (-CH2O-) as its unit structure. Two forms of POM material exist, both functionally the same but with slight performance differences.

POM Processing

Like other engineering plastics, POM processing uses several techniques, including injection molding, extrusion, blow molding and machining.

Processing methods are selected based on product specifications (e.g., desired shape) and production volume. Regardless of which method is chosen, there are a few important considerations when using POM resin, including:

- Drying:

Crucial to avoid defects caused by moisture

- Temperature control:

Essential to preventing degradation and guaranteeing the quality of the final product

- Mold design:

Must account for shrinkage, which is typical for POM

Why use POM material?

POM is known to have some of the highest abrasion resistance among plastics and exhibits, POM displays desirable features, including:

- Withstands friction and erosion

- Self-lubricating

- High strength and elastic modulus

- Creep resilience

- Dimensional stability

- Low water absorption

- Rapid crystallization

- Solvent and oil tolerance

Even with these beneficial characteristics, POM material has some disadvantages. Its high crystallinity means it is not transparent, and there aren’t any adhesives, making welding a requirement for bonding. Additionally, it is not as weather-resistant, flame-retardant or acid-resistant as other plastics.

What is polyoxymethylene (POM) used for?

POM material is ideal for parts that operate machines like gears, bearings and springs and is also found in:

- Electronics:

Cameras, mobile phones, computer peripherals, printers and copiers.

- Automobiles:

Fuel caps, fuel pump modules, seat belts and interior parts.

- Home appliances:

Washing machines and dryers, refrigerators and freezers, vacuum cleaners.

- Consumer goods:

Toys, zippers, buckles and musical instruments.

- Mechanical applications:

Rollers for transport equipment, reduction mechanisms, chains and watch parts.

It’s often asked, “Is POM material expensive?” It’s a good question. While it is not the least expensive engineering plastic, its performance benefits — like excellent abrasion resistance and strength — often justify the costs.

Polyoxymethylene FAQs

Q: Is POM FDA approved?

A: Depending on the intended use and formulation, POM is FDA approved.

Q: Is POM stronger than nylon?

A: Neither material is stronger than the other. POM is a better choice for tensile strength and rigidity, while nylon is better for flexibility and impact resistance.

Q: What is an alternative to POM plastic?

A: Depending on the desired properties, POM alternatives include polyamide (nylon),

polypropylene (PP), polyethylene (PE), polyetheretherketone (PEEK), acrylonitrile butadiene styrene (ABS), high-density polyethylene (HDPE), polycarbonate (PC) and polytetrafluoroethylene (PTFE).

Q: Is POM plastic toxic?

A: In its solid form, POM does not have notable health risks and is safe to handle.

Q: Can you recycle POM?

A: Yes, it can be recycled, but the qualities may break down with each use.