Polyoxymethylene (POM) Properties

Polyoxymethylene, sometimes called polyformaldehyde or polyacetal, is a polymer containing oxymethylene (-CH2O-) as its unit structure.

19/08/2025

By Web Editorial Team

3min read

Polyoxymethylene, sometimes called polyformaldehyde or polyacetal, is a polymer containing oxymethylene (-CH2O-) as its unit structure.

19/08/2025

By Web Editorial Team

3min read

Polyoxymethylene, sometimes called polyformaldehyde or polyacetal, is a polymer containing oxymethylene (-CH2O-) as its unit structure. There are two types of POM plastic material:

Homopolymer: Polymerizing formaldehyde only

Copolymer: Adding ethylene oxide to formaldehyde

Delrin material (i.e., homopolymer) was first produced in 1959 by DuPont, while Celcon® (a brand name for the copolymer) was first produced by Japanese-based Celanese Corporation in 1962.

So, is POM material expensive? That is determined by whether it’s a homopolymer or copolymer, but generally, it falls in the middle of the cost spectrum. The high-performing properties make it more expensive than polypropylene (PP) or polyethylene (PE) but more affordable than polycarbonate (PC).

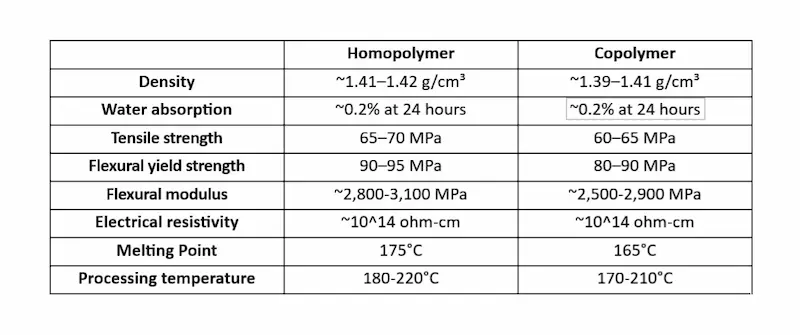

Although POM resin uses both homopolymers and copolymers and they are functionally the same, some of their key properties and performance slightly differ.

Looking at these figures, it’s often asked how durable is POM? And is POM plastic soft? All polyacetal is considered highly sturdy with excellent dimensional stability. It is not soft, and its rigidness makes it ideal for applications that require repeated motion or in high-stress environments.

POM processing methods are selected based on product specifications (i.e., desired shape) and production volume. Regardless of which method is chosen, drying temperature and mold design are important considerations.

With all its advantages, there are also some disadvantages of POM material. Its high crystallinity means it is not transparent, and there aren’t any adhesives, making welding a requirement for bonding. Additionally, it is not as weather-resistant, flame-retardant or acid-resistant as other plastics.

As with any engineered plastic, there are questions surrounding POM plastic material safety, like:

Q: Is POM plastic toxic?

A: In its solid form and under normal use, POM material does not have notable health risks and is safe to handle.

Q: Is POM FDA approved?

A: Yes, depending on the intended use and formulation, POM resin is FDA approved under regulation 21 CFR 177.2470.

Q: Is POM material food grade?

A: Due to its excellent mechanical properties, chemical resistance and low moisture absorption, POM is considered safe for contact with food.

What is polyoxymethylene used for?

POM material has excellent abrasion resistance and strength, making it a favorite material for t a wide variety of applications including:

Automotive: fuel pumps, seat belts, door locks, shift levers, switches, gasoline pumps

Appliances: washing machines, refrigerators, dishwashers, blenders, vacuum cleaners

Office equipment: printers, copiers, staplers, furniture, paper shredders

Mechanical parts: rollers for transport equipment, reduction mechanisms, chains, watch parts

Consumer goods: Toys, zippers, buckles, skateboards, fishing reels, board games

Finding a suitable material to replace POM depends on the application's specific requirements, like strength, degradation resilience, moisture resistance and cost. Five common alternatives include:

With versatility as both a homopolymer and copolymer, the unique blend of strength, low friction and dimensional stability makes POM plastic a go-to material for modern manufacturing.

29/01/2026

By Web Editorial Team

2min read

17/01/2026

By Web Editorial Team

1min read

20/12/2025

By Web Editorial Team

2min read

02/12/2025

By Web Editorial Team

2min read

Copyright© 2026 PlaBase. All Rights Reserved.