What is polypropylene plastic, and what makes it so popular? In a previous blog, we discussed PP's role as a versatile thermoplastic widely used for its strength and cost-effectiveness. Now, let’s dig deeper into its characteristics.

How is polypropylene made?

PP is the ISO abbreviation for polypropylene, a polyolefin plastic made from propylene (an olefin compound). Crude oil is used to make a liquid called naphtha, which is cracked to yield propylene; the propylene is then polymerized under heat and pressure. This process produces polypropylene, (C3H6)n, where "n" represents the number of repeating units.

PP is mainly a homopolymer made from propylene, but copolymers are also made with other raw materials (comonomers). It is classified into three types:

- Homopolymer: A polymer made from a single monomer (propene).

- Block copolymer: Polypropylene copolymer using continuous blocks of one monomer followed by blocks of another monomer

- Random copolymer: PP copolymer where monomers are distributed randomly along the polymer chain without a specific pattern

Polypropylene properties

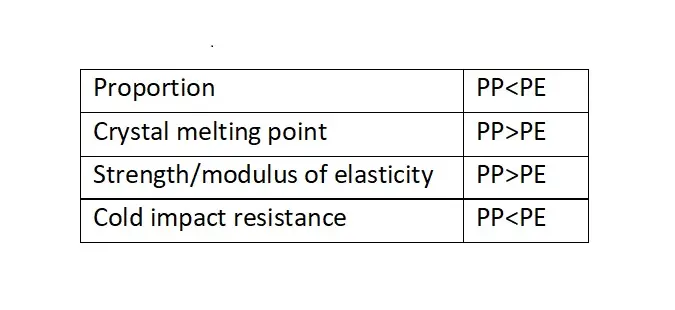

Though PP has properties similar to PE, it has better mechanical properties, and the melting temperature of polypropylene (crystalline melting point) is higher. Here’s a comparison of

the basic elements of both plastics:

Additionally, key benefits to using PP include:

- The smallest specific gravity of all plastics, ranging from 0.89-0.92g/cm³.

- Minimal water absorption at less than 0.01%.

- Effective impact resistance, particularly in copolymer PP, which shows better low-temperature impact resistance.

- Moderate friction and wear at low speeds, which can be improved by additives.

- Excellent chemical resistance to a broad range of chemicals, solvents and corrosives offers broad chemical compatibility.

- A melting temperature of 160–170 °C allows PP to be easily formed and molded.

- High dielectric strength (25-50 kV/mm) and arc resistance make PP a popular choice for electrical insulation.

Polypropylene products

PP can be processed using injection molding, extrusion molding, blow molding and vacuum molding, but any of these methods are possible by adjusting the molecular weight of polypropylene resin. Some common uses are:

- Automotive: bumpers, bumper beams, instrument panels, trim

- Home appliances: washing machine tubs, refrigerator trays, rice cooker housings

- Everyday items: caps, bottles, clothing cases, food packaging, toilet seats

- Medical equipment: syringes, infusion bottles, pipettes

Polypropylene is one of the most recycled plastics worldwide. It contributes to the circular economy and is vital to sustainable waste management practices.

What are the disadvantages of polypropylene?

Polypropylene has many good points, but it also has some weaknesses. For example, its poor weather resistance (including UV) means it turns white when exposed to sunlight. Additionally, PP is inherently flammable, and while the temperature needed to ignite it is high (300 to 400°C), it burns quickly once started. Other weaknesses include difficulty bonding and poor printability. Research and development are ongoing to address and overcome these weaknesses.

PP: Low-cost strength

Given its reliability and safety, it is clear why polypropylene is one of the most frequently used plastics.