Sustainable Plastics: From Plants to Plastic

Creating eco-friendly change is a hot topic in the plastics industry as more consumers have started asking, “How long does it take for plastic to biodegrade?”

21/09/2025

3min read

Creating eco-friendly change is a hot topic in the plastics industry as more consumers have started asking, “How long does it take for plastic to biodegrade?”

21/09/2025

3min read

Creating eco-friendly change is a hot topic in the plastics industry as more consumers have started asking, “How long does it take for plastic to biodegrade?”

The answer isn’t always straightforward, so today we’re going to review sustainable plastics and plastic solutions.

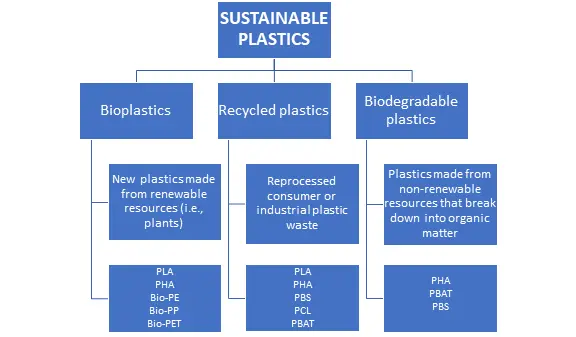

Though traditional plastics' functional properties benefit industries and economies worldwide, their environmental impact remains a cause for concern. Sustainable plastics are dependable, eco-friendly alternatives designed to reduce energy use, eliminate fossil-fuel dependence and divert waste. Sustainable plastic types include:

It’s estimated that a dozen or more sustainable plastics are currently being used, but ongoing research and development means that number continues to grow. Nonetheless, it’s often asked what the most eco-friendly plastic is. While bioplastics like polylactic acid (PLA) and

bio-polyethylene (Bio-PE) are popular, the most sustainable plastic is polyhydroxyalkanoate (PHA). This fully biodegradable option is non-toxic, versatile and breaks down in marine

environments without harming ecosystems.

Like recycled plastics, bioplastic and biodegradable plastic are essential to ongoing eco-friendly efforts. Their differences lie in how they’re sourced versus how they break down.

The characteristics of eco-friendly plastics frequently offer the same benefits as traditional, fossil fuel-based plastics. We outline a handful of their properties below.

Density | Water absorption | Melting point | Flammability | Electrical resistance | Tenacity | Tensile strength |

1.2-1.4 g/cm³ | Higher in starch-based plastics | 100-180°C | Comparable (produces non-toxic by-products) | Comparable | Moderate to high | 20-70 MPa |

*These figures can vary based on source material, additives and other factors.

From disposable tableware like biodegradable plastic straws or biodegradable plastic cups to agricultural products, many industries are taking advantage of sustainable plastic solutions. Below is a sample of markets and products making eco-friendly changes:

The pressure to transition to bio-based plastics comes with added demands for sustainable raw materials; however, these demands are often met with a struggling supply chain. Amongst the most significant issues are sourcing crops and agricultural land without endangering food production. Furthermore, plastic production infrastructure is still developing, making it less efficient than conventional plastics.

Additionally, these shortages also cause raw material pricing instability. However, shortages don’t solely dictate prices; external factors like international events, differences in currency rates, and higher transportation rates can cause prices to fluctuate. Regrettably, this means plastic manufacturers must be willing to pay a premium for eco-friendly materials.

Eco-friendly plastics are a promising alternative to fossil fuel based, traditional materials. They provide a pathway to eliminating wasteful manufacturing and minimizing environmental impact. Through continued research and consumer adoption, making sustainable change is achievable.

29/01/2026

By Web Editorial Team

2min read

17/01/2026

By Web Editorial Team

1min read

20/12/2025

By Web Editorial Team

2min read

02/12/2025

By Web Editorial Team

2min read

Copyright© 2026 PlaBase. All Rights Reserved.